ARGON

APPLICATION:

Shielding gas for TIG (GTAW), MIG (GMAW) welding technologies. These Arc welding technologies are usually used for welding of high grade metals and alloys, non ferrous metals and thin material thicknesses with inert shielding gas protecting welding bath against surrounding atmosphere. Shielding gas supply is one of the key factors to keep high quality welds and good efficiency of the welding process. Smooth and constant gas flow enables welding of the most demanding metals and their alloys as Titanium, Aluminium and Stainless steel of various grades. Pressure regulator needs to prepare defined parameters of the gas supply to the technology and should avoid any pollution of the high quality shielding gas.

Shielding gas for TIG (GTAW), MIG (GMAW) welding technologies. These Arc welding technologies are usually used for welding of high grade metals and alloys, non ferrous metals and thin material thicknesses with inert shielding gas protecting welding bath against surrounding atmosphere. Shielding gas supply is one of the key factors to keep high quality welds and good efficiency of the welding process. Smooth and constant gas flow enables welding of the most demanding metals and their alloys as Titanium, Aluminium and Stainless steel of various grades. Pressure regulator needs to prepare defined parameters of the gas supply to the technology and should avoid any pollution of the high quality shielding gas.

Gas Economiser:

Gas Economiser:

Why should I use Gas Economiser?

BECAUSE IT HELPS TO SAVE UP TO 40% OF MY SHIELDING GAS!

Cost of the shielding gas is important factor influencing total cost balance of the welding operation. The savings with GCE economiser represents up to 0,5ltr of the shielding gas on each average weld. Optimal gas delivery with proper defined pressure and flow-rate improves quality of welding. Cost saving and quality improvement in this area give the advantage to the user on the competitive market.

What is Gas Economiser?

It is pressure regulator with saving function. It is used as cylinder regulator installed directly on the cylinder with shielding gas. It contains integrated economiser which is eliminating gas waste when gas flow is exceeding requested flow-rate. The GCE Gas economiser can be used for shielding gas arc welding as MIG, MAG and TIG welding technologies.

The range of Gas Economisers:

- Ecosaver

- Ecosaver+

- GS40

__________________________________________

GAS PROPERTIES

- Colorless gas

- Odorless

- Tasteless

- Non - flammable

- Non - toxic

- Non - explosive

- Heavier than air

- Chemical formula: Ar

- Gas symbol: N

Boiling point: -185,9 °C at 1,013 bar

- Melting point: - 189,4°C at 1,013 bar

- Gas density: 1,67 kg/m3 at 1,013 bar and 15°C

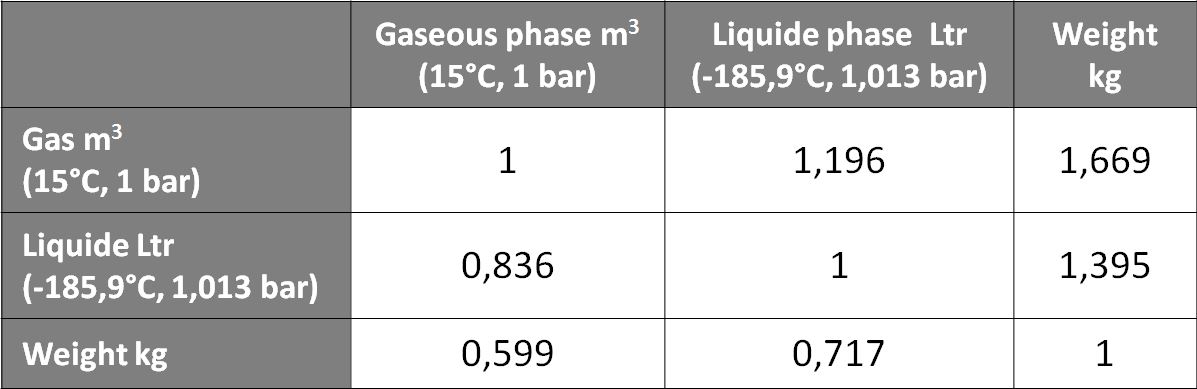

Conversion of gas volume in liquid and gaseous phase

__________________________________________

PRODUCTS

| Product | Picture | Inlet pressure | Outlet flow/pressure | Remark |

| Unicontrol | 200 bar 300 bar |

16 l/min |

Single stage | |

| 200 bar 300 bar |

10 bar 20 bar |

Single stage | ||

| Fixicontrol | |

200 bar 230 bar |

24 l/min |

Single stage |

| Multistage | |

200 bar 300 bar |

35 l/min |

Two stage |

| Basecontrol | |

230 bar | 24 l/min | Single stage |

| Ecosaver | |

200 bar 300 bar |

30 l/min |

Gas Economiser |